Product description

Description

Standard sizes available with various cross section

Various Watt Density options available.

Robust Design with Choice of Terminal Exits

Designed for even heat profile

Precision fit on Hot Runner Nozzles & Manifolds

Highly Non-corrosive

Maximum heat transfer due to more contact area

Advanced Thermal Engineering

CE Certified

Available with built in Thermocouple

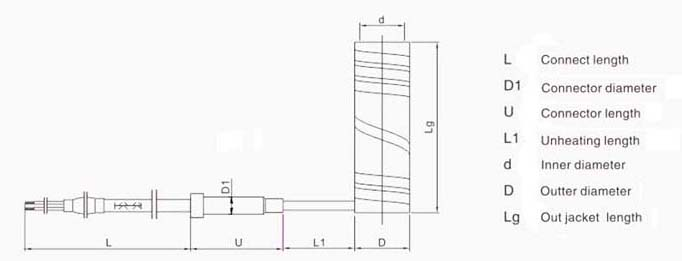

Coil Heaters Parameter

Specification:

2.Usually,coil heaters are configured as small diameter,high performance nozzle heaters that are fully annealed.

3.Coil heates are use on injection molding machine nozzles and sprue bushings supplying bushings supplying 360 degree of heat with optional distributed wattage available.

4.Coil heaters are also used as cartridge heaters where irregular size bores are found.A straight,round cable heater can snake through a seal in packaging equipment installations.

Coil Heaters Application

Hot Runner Nozzles & Bushings.

Hot runner Injection moulds

Injection & Blow Moulding Machine Nozzles.

PET prefrom & Thin wall container Moulds.

Hot runner Manifolds.

Please feel free to contact me