Product description

Thermocouple extension wire is used to extend the thermode, that is, the cold junction of the movable thermocouple connect with indicating instrument to make up temperature measurement system.

Extension wire falls into two kinds; one is extension type and the other is compensation type. The wire same with the two thermocouple wires of the Graduation Mark, is know as the extension type. The wire same with, formed by cooper—-cupronickel materials with different proportion, is called compensation type.

The two kinds of extension wire, both have good property of resistance to acid, alkali, abrasion and fire. It’s temperature range used commonly is -25-400C. In addition, it can be used for a long time by immersing into the oil. The extension wire complies with GB/T4989-94-2016 standard.

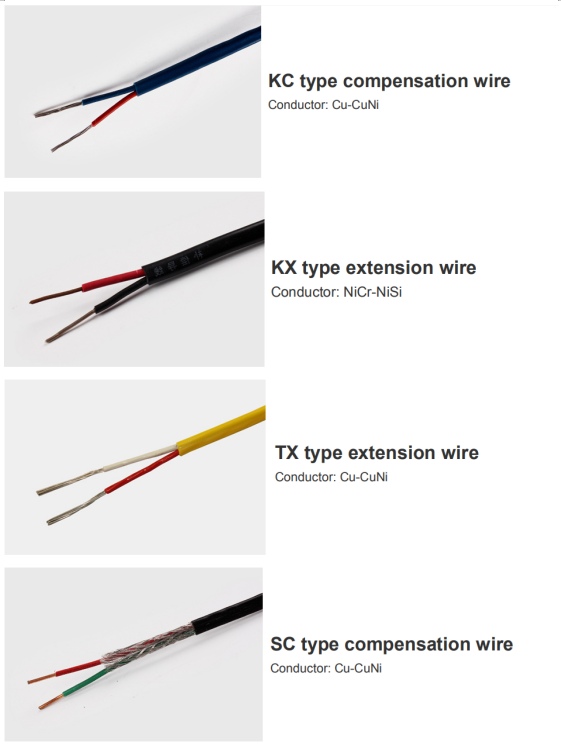

The extension wire types can be divided into WC, BC,SC, RC, NX, KC, KX, EX, JX and TX in accordance with the product type.

PVC insulated thermocouple wire and thermocouple extension wire–Single pair

. Continuous use up to 105°C

. Short term use up to 150°C

. Fire and flame retardant

. Very good chemical, abrasion, moisture and scratch resistance

PVC-PVC Physical Properties

Nominal Insulation Thickness:

| Wire Size (AWG) | Conductor Insulation Thickness (mm) | Jacket Insulation Thickness (mm) | Outer Diameter (mm) |

| 16 | 0.45 | 0.80 | 4.6X6.8 |

| 16 7/24 | 0.45 | 0.80 | 4.6X6.8 |

| 20 | 0.35 | 0.60 | 2.8X4.0 |

| 20 7/28 | 0.35 | 0.60 | 2.8X4.0 |

| 24 | 0.35 | 0.60 | 2.4X3.7 |

| 24 7/32 | 0.35 | 0.60 | 2.4X3.7 |

| 26 | 0.30 | 0.60 | 2.0X3.1 |

| 28 | 0.30 | 0.60 | 2.0X3.1 |

| 30 | 0.30 | 0.60 | 2.0X3.1 |

Applications

* Metallurgy

* Chemical industry, petroleum

* Power generation

* Defense and scientific research

* Cables for connection between thermocouples and temperature display instrument.\

Features

- Continuous temperature rating: 105°C

- Additional abrasion resistance with optional stainless steel and tinned copper wire overbraids.

- Custom constructions available.

| Thermocouple extension type | Thermocouple extension type | ANSI Color Code | ANSI Color Code | Initial Calibration Tolerances | Initial Calibration Tolerances | Initial Calibration Tolerances |

| Wire Alloys | Calibration | Conductor (+/-) | Jacket | Temperature Range | Standard Limits | Special Limits |

| Iron (+) vs. Constantan(-) | JX | White/Red | Black | 0°C to +200°C | ± 2.2°C | ± 1.1°C |

| Chromel (+) vs. Alumel (-) | KX | Yellow/Red | Yellow | 0°C to +200°C | ± 2.2°C | ± 1.1°C |

| Copper(+) vs. Constantan(-) | TX | Blue/Red | Blue | -60°C to +100°C | ± 1.1°C | ± 0.5°C |

| Chromel(+) vs. Constantan(-) | EX | Purple/Red | Purple | 0°C to +200°C | ± 1.7°C | ± 1.1°C |

| Nirosil (+) vs. Nisil (-) | NX | Orange/Red | Orange | 0°C to +200°C | ± 2.2°C | ± 1.1°C |

| Copper (+) vs. Alloy 11 (-) | RX/SX | Black/Red | Green | 0°C to +200°C | ± 5°C | – |

| Copper S (+) vs. -Copper E (-) | BX | Gray/Red | Gray | 0°C to +200°C | ± 3.7°C | – |

Color Code & Initial Calibration Tolerance for Thermocouple Wire:

| Thermocouple type | Thermocouple type | ANSI Color Code | ANSI Color Code | Initial Calibration Tolerances | Initial Calibration Tolerances | Initial Calibration Tolerances |

| Wire Alloys | Calibration | Conductor (+/-) | Jacket | Temperature Range | Standard Limits | Special Limits |

| Iron(+) vs. Constantan(-) | J | White/Red | Brown | 0°C to +285°C 285°C to +750°C | ± 2.2°C ± 0.75% | ± 1.1°C ± 0.4% |

| CHROMEL(+) vs. ALUMEL(-) | K | Yellow/Red | Brown | -200°C to -110°C -110°C to 0°C 0°C to +285°C 285°C to +1250°C | ± 2% ± 2.2°C ± 2.2°C ± 0.75% | ± 1.1°C ± 0.4% |

| Copper(+) vs. Constantan(-) | T | Blue/Red | Brown | -200°C to -65°C -65°C to +130°C 130°C to +350°C | ± 1.5% ± 1°C ± 0.75% | ± 0.8% ± 0.5°C ± 0.4% |

| CHROMEL(+) vs. Constantan(-) | E | Purple/Red | Brown | -200°C to -170°C -170°C to +250°C 250°C to +340°C 340°C+900°C | ± 1% ± 1.7°C ± 1.7°C ± 0.5% | ± 1°C ± 1°C ± 0.4% ± 0.4% |

Images