An industrial heating element provides heat in a variety of capacities for manufactures and producers of every imaginable product. With such a wide variety of heating element options, it can be a challenge to find the prefect element for your task. The first step toward choosing the most efficient and effective heating element for any process starts with the identification of some of the main types of heating elements available for industrial use.

Immersion elements: Immersion heaters quickly heat liquids for different industrial uses. Usually immersion elements use direct heat transfer to achieve the necessary temperatures. Immersion heaters are commonly used in chemical processes.

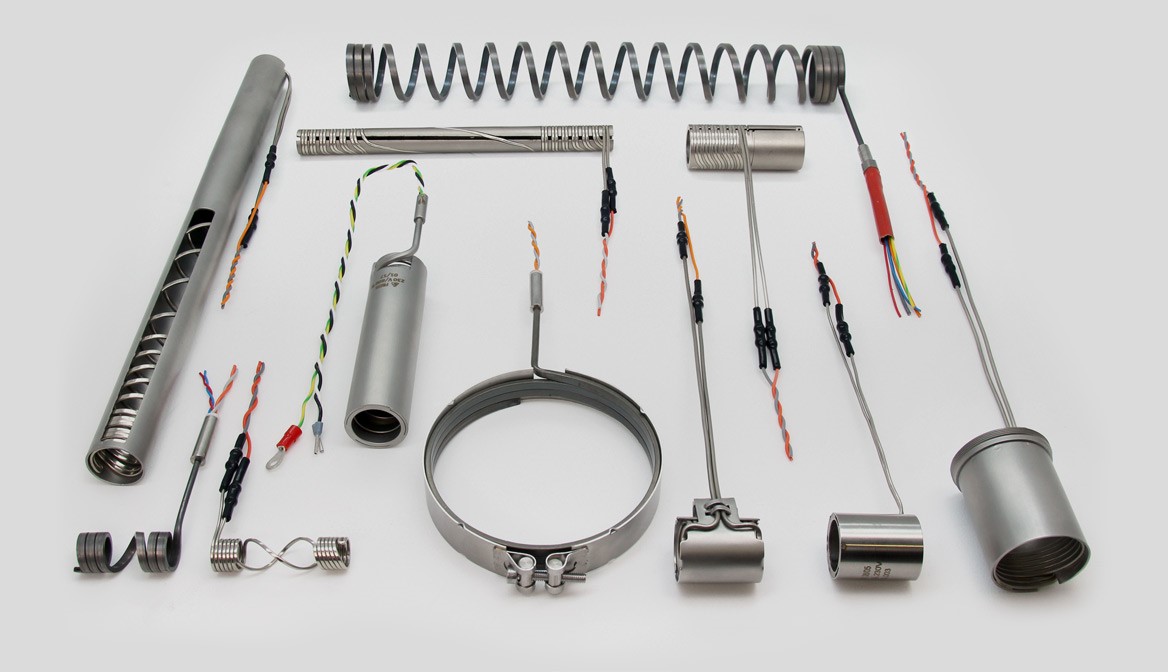

Tubular heaters: Tubular heating elements are some of the most common forms of industrial heating elements. Tubular heaters use heated tubes formed into a variety of shapes to heat products. Tubular heaters are used for heating liquids, gasses, and solids. Tubular heating is used for convection heating, radiant heat, and conduction heating.

Flanged heaters: Flanged heating elements apply direct heat to liquids and can contain both hairpin and tubular heating elements contained in a small sheath. Flanged heaters are often used in oil heating, gas heating, wax heating, and corrosive solutions.

Screw plug heating elements: Screw plug heaters encase hairpin heating elements inside small tubing. One side of the element can screw into a container to easily monitor and control the heat in a smaller container. Screw plug heaters are commonly used in heating gasses and liquids.

Cartridge heaters: Cartridge heating elements look like florescent light bulbs. They have a long tubular shape with wires coming out of one end to connect to an energy source. Cartridge heating elements are often used to heat solid materials to high temperatures. Cartridge elements have use for heating metals and other solids to high temperatures to increase the flexibility of the solid.

Knowing the variety of heating options available can help any manufacturer choose the best heating elements for their processes.