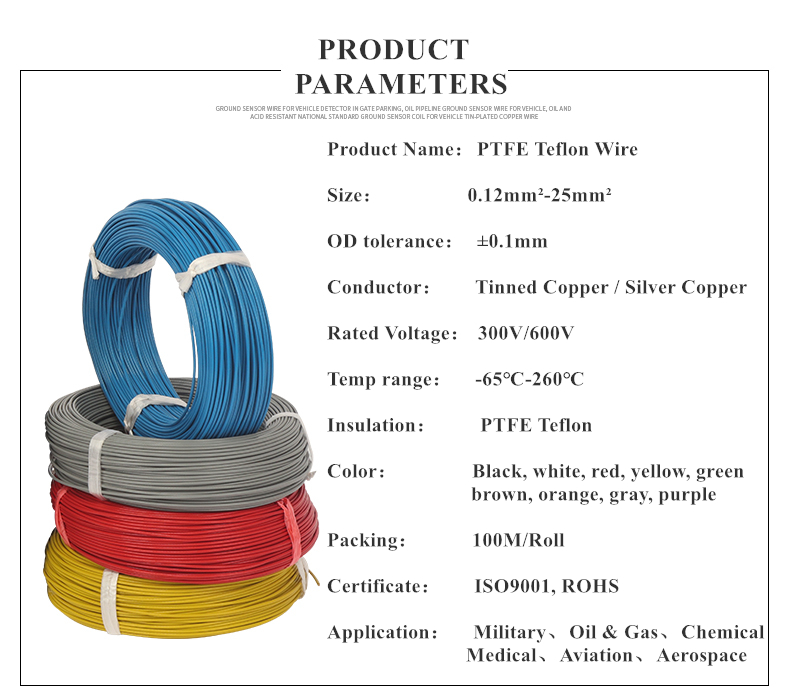

Product description

What is PTFE?

A fluorinated thermoplastic with outstanding thermal, physical, high strength, and electrical properties. PTFE is generally restricted to applications requiring its special characteristics because its basic resin and processing costs are relatively high.

Features & Advantages of PTFE Hook Up Wire:

PTFE is especially suitable for internal wiring-soldering applications where insulation melt back is a specific problem. PTFE insulation is outstanding in its resistance to oil, oxidation, heat, sunlight, and flame; and also in its ability to remain flexible at low temperatures. The PTFE insulated wire has excellent resistance to: Ozone, Water, Alcohol, Acids, Alkalis, Aromatic hydrocarbons, Solvents.

Common applications of PTFE:

PTFE hook up wire products are highly recommended for miniature cable applications because of their superior thermal and electrical properties. PTFE is commonly used in industries lie military, aerospace, and oil & gas.

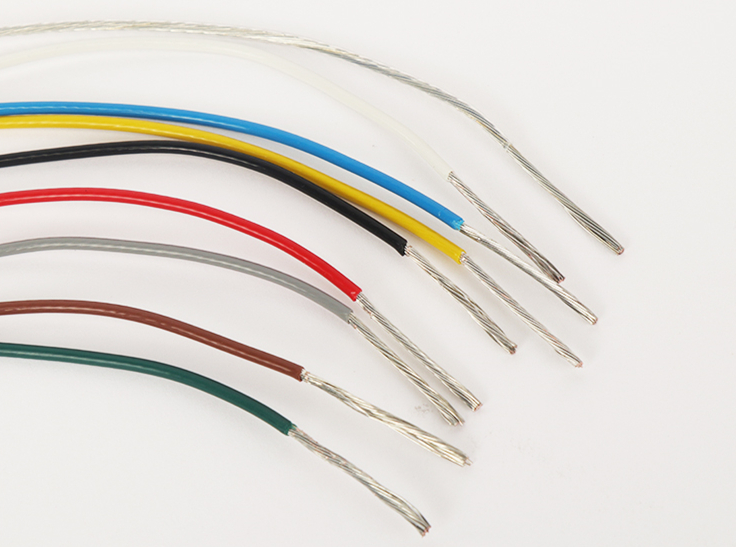

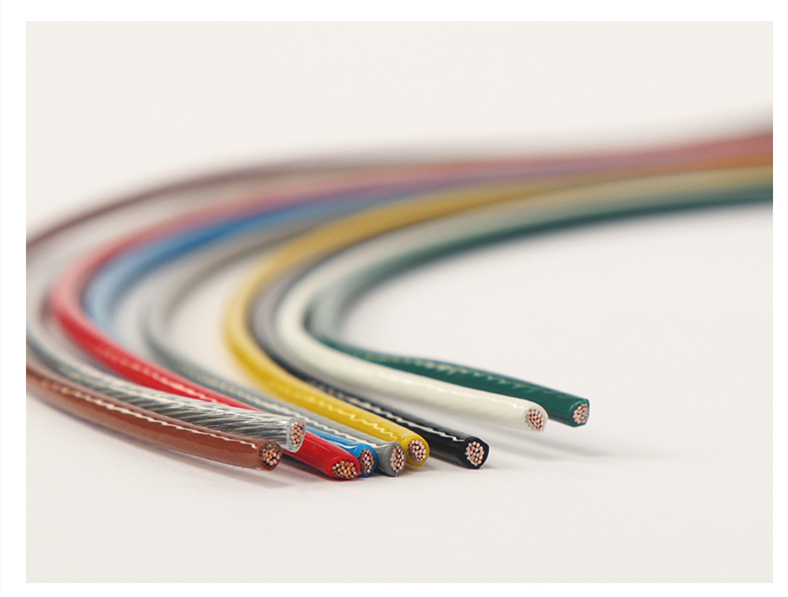

Product display

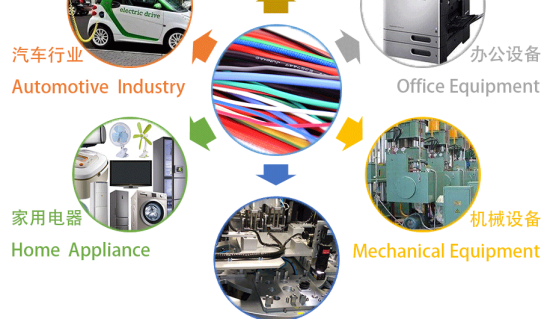

Application

Contact Me