Product description

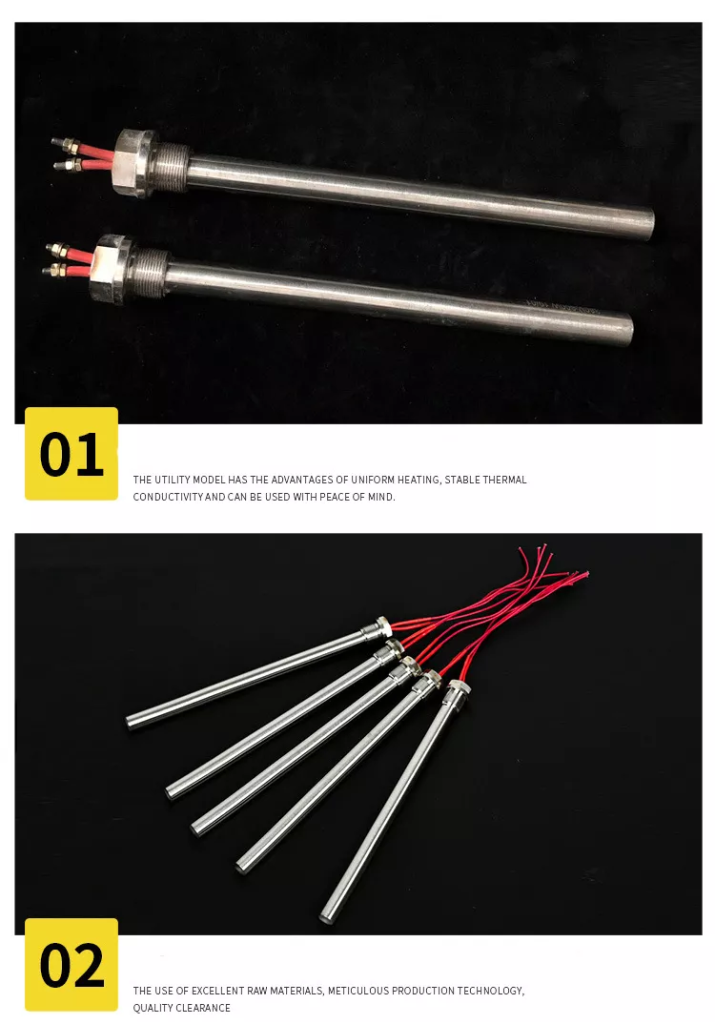

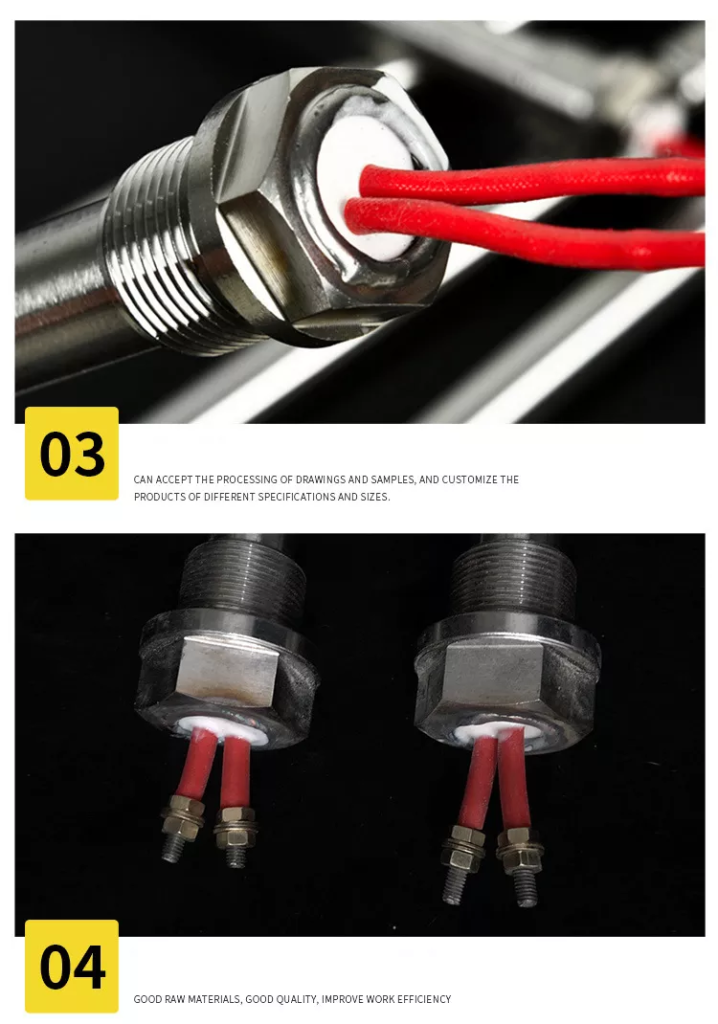

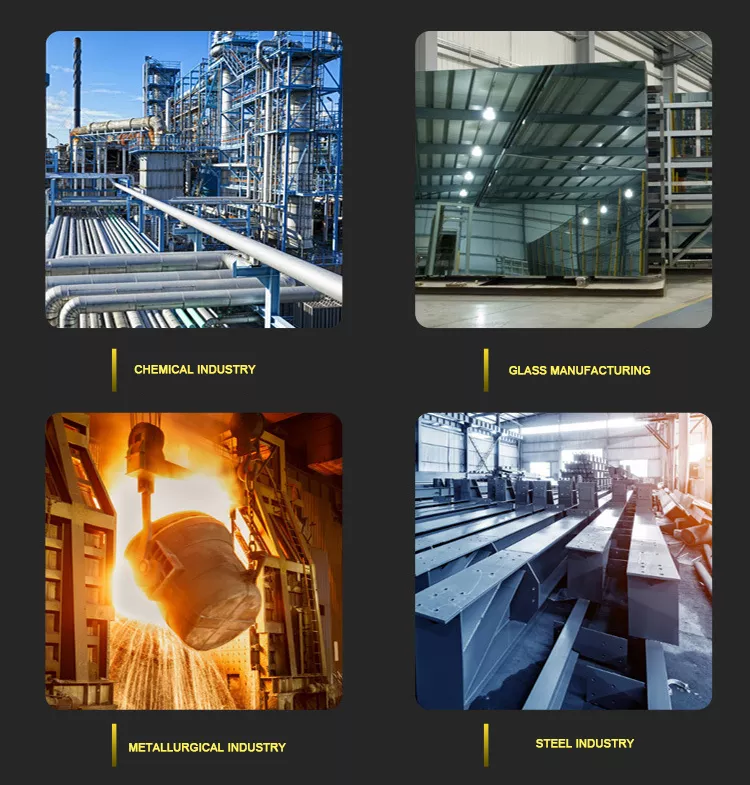

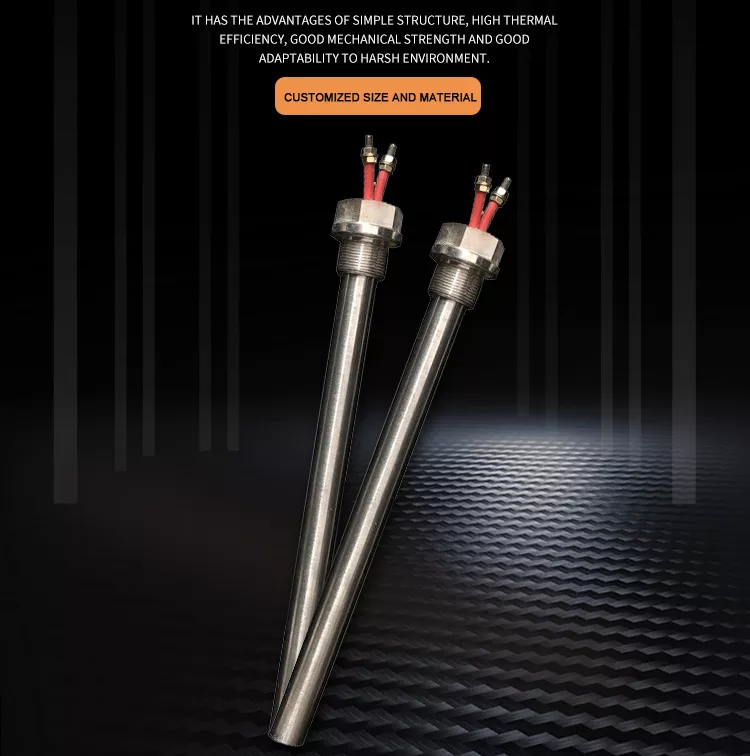

ubular heaters are custom designed in a various shapes to as client’s requirements for direct immersion in liquids such as water, oils, solvents and process solutions, molten materials as well as air and gases. Tubular heaters are produced using Incoloy, stainless steel or copper sheath materials and also there is huge variety of selection of termination styles available. Insulation of Magnesium offers greater heat transfer. Tubular heaters can be used in any application. Straight tubular can be inserted in machined groves for conductive heat transfer and formed Tubular provides consistent heat in any type of special application. Its applications areas are: Plastic processing machineries ;Engineering Industry ;Packaging machinery ;Shoe making machineries ;Foundry Equipment ;Radiant Surface heating ;Hot Runner Mould Systems etc.

Product specifications: multiple specifications are available, support non-standard customization

Product use: can be used in a variety of environments

Normal material: carbon steel, 201 stainless steel, 304 stainless steel, 316 stainless steel, 310S stainless steel, titanium alloy